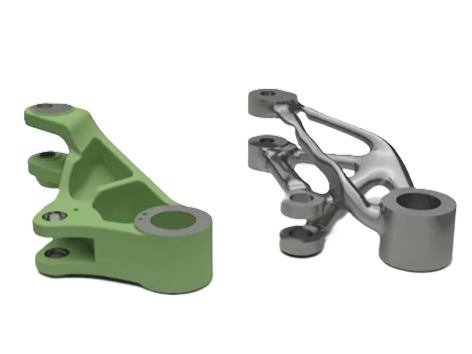

Designed for Additive Manufacturing

With over 14 years of experience in designing components specifically for additive manufacturing (3D printing). We have the expertise to guide you through every layer of the production process.

From design, prototyping, to mass production. We will ensure your parts will meet all of your requirement, function, and that it’s optimized for mass production with additive manufacturing.

Benefits of Additive Manufacturing

Material Selection

-

For our consumer grade, we offer PLA, PETG, High Temp PETG, TPU, TPE.

These material coverage range:

Tensile Strength: 60 MPa

Flexural Modulus: 2400 MPa

HDT: 70C (@ 0.45MPa) -

For our engineering grade, we offer PET, PCTG, ABS, ASA, Nylon (PA6, PA12), Polycarbonate.

Many of these also can be combined with glass or carbon fiber (GF/CF).

These material coverage range:

Tensile Strength: 80 MPa

Flexural Modulus: 3,800 MPa

HDT: 130C (@ 0.45MPa) -

For the most demanding environment, we offer:

PETG-GF/CF/ESD, PET-CF, PA612-GF/CF, PPS, PEEK, PEI/Ultem, and other Metal substitute.

These material coverage range:

Tensile Strength: 200 MPa

Flexural Modulus: 8,600 MPa

HDT: 250C (@ 0.45MPa)

Geometry

Optimization

What we offer

Manufacturing Consultation

Unsure of where to even start? We can sit down with you, run you through the entire design, prototype, and production process. To help you fully understand the path need to take to make your ideas a reality.

Design Optimization

Bring us your existing CAD files and we’ll help you modify your part so it can be manufactured more efficiently for additive manufacturing.

Accepted CAD Files: STEP, STP, IGES, IGS, SLDPRT, 3DM, STL, OBJ

Design from Scratch

Bring us your ideas, drawings. We’ll work with you to come up with a final design that is optimized for 3D printing, and ready for mass production.